DIY - AUTOMATIC SWING GATE

Want to install your own automatic swing gate. No problem. Automatic Solutions has all the gear your need to build and install an automatic swing driveway gate. You don't even have to make the gate if you choose. We have a range of Easy Gate kits at a prices so low you will probably pay more just for the material and components. We also have flat pack gates cut to size or custom made to your design.

Note: The information on this page is intended as a guide only representing a typical installation. Dimensions will vary dependent on your gate type and running gear setup.

ON THIS PAGE

Planning and preparation

Mounting your motor

Gate stops

Ready to power and program.

Planning and preparation. The more time you spend at this stage the less mistakes made and time wasted doing re-work, so spend a bit of time getting this part right. There are simply hundreds of ways to hang swing gates so we will concentrate here on a typical setup that allows for automation. Any swing gate has only a few key parts that need consideration - the posts, the gate/s, and the hinges. Granted, the automation section has many more considerations but just for the moment we will concentrate our planning on the basics, as they remain constant whether the gate is automated or not.

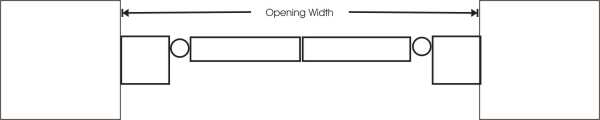

The first thing you need is two definable points to determine the gate opening. You may have existing brick or concrete piers or possibly between two walls. If not you will need to allow for the installation of posts or piers.

If you are installing new posts I would suggest 100mm square or 125 x75 as a good size and if concreting into the ground a minimum of 600mm in concrete with legs attached. (See section on post installation). Note consideration has to be given during post selection as to the room required for your motor. Some motors will need the 125mm offered by the wider post.

Once you have determined your two points you can start to look for and record some information - 1. The opening width between the two posts or piers. 2. From this you need to make deductions to allow for clearances. In the example above I have an opening width of 3200mm and wish to install a pair of automatic swing gates. I have checked and my motors fit perfectly behind the 100mm posts. Therefore my calculations will go like this -

3200 opening width less 200mm for two posts leaves me 3000mm.

3000mm less 150mm for hinges (I have chosen "Big Hinges" that need 75mm per side). This leaves me with 2850mm.

2850mm less 20mm gap in the centre of my two gates leaves me 2830mm

2830mm divided by two gives me 1415mm each as the width for my gates.

Your Automatic Solutions branch will help you choose hinges, motors etc. and advise deductions required. You can also e-mail us here for help and upload photos if you have them.

3. Now you want a height. In the example above I want a finished height of 1800mm. My centre stop for my gates requires a minimum clearance of 20mm and maximum of 40mm. I will deduct 25mm from my 1800 and make my gates 1775mm high. By the way based on this I can make my posts 2700 long (1800mm plus 900mm into the concrete) unless of course I am bolting my posts to the wall in which case I will cut them at 1800mm long.

Mounting your motor. Each motor will have a slightly different mounting method and dimensions but there are a number of key points to take into account when considering mounting your motor.

If your motor can swing from the centre of the gate vertically this will better than the bottom. Apart from a simple mechanical advantage it keeps it off the ground where dirt and dust will penetrate with ease. Your post mounted bracket can be fixed in a variety of ways. Welding is popular although we prefer using tek screws or bolting. Assuming you have used a reasonable thickness for your post (3mm) then the teks will hold perfectly well for normal operation but will in all likelihood shear if excess force is applied saving any damage to your motor and allowing easy refit. The bracket on your gate may need to be welded or bolted as this point takes a lot of pressure. Use tek screws to position and test. When happy with your result bolt or weld.

Gate Stops. All automatic gates require opening and closing stops for safety and programming. On single swing gates this generally means a good secure opening stop and often an electric gate lock takes care of the closing stop. Double gates is a little more complex as now we need two opening stops and a centre stop. Do not be tempted into using built in motor stops as a replacement for good solidly installed gate stops. The built in devices work ok on small open design gates as opening stops but cause nothing but frustration as closing stops. Put in good mechanical stops and save the maintenance and frustration.

Ready to power and program. At this point I assume you have had your power professionally connected and all other wiring has been completed. My simple suggestion is that you leave most extras like photo cell beams and keypads not connected and that you have all required loops installed until you have the gate programmed and running. Having bells and whistles connected will only complicate matters if things don;t go exactly as expected. By having the bare basics makes fault finding much easier.

ON THIS PAGE

Planning and preparation

Mounting your motor

Gate stops

Ready to power and program.

Planning and preparation. The more time you spend at this stage the less mistakes made and time wasted doing re-work, so spend a bit of time getting this part right. There are simply hundreds of ways to hang swing gates so we will concentrate here on a typical setup that allows for automation. Any swing gate has only a few key parts that need consideration - the posts, the gate/s, and the hinges. Granted, the automation section has many more considerations but just for the moment we will concentrate our planning on the basics, as they remain constant whether the gate is automated or not.

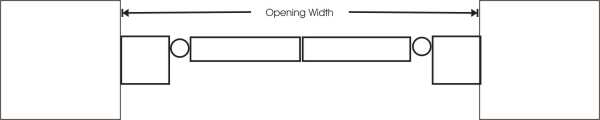

The first thing you need is two definable points to determine the gate opening. You may have existing brick or concrete piers or possibly between two walls. If not you will need to allow for the installation of posts or piers.

If you are installing new posts I would suggest 100mm square or 125 x75 as a good size and if concreting into the ground a minimum of 600mm in concrete with legs attached. (See section on post installation). Note consideration has to be given during post selection as to the room required for your motor. Some motors will need the 125mm offered by the wider post.

Once you have determined your two points you can start to look for and record some information - 1. The opening width between the two posts or piers. 2. From this you need to make deductions to allow for clearances. In the example above I have an opening width of 3200mm and wish to install a pair of automatic swing gates. I have checked and my motors fit perfectly behind the 100mm posts. Therefore my calculations will go like this -

3200 opening width less 200mm for two posts leaves me 3000mm.

3000mm less 150mm for hinges (I have chosen "Big Hinges" that need 75mm per side). This leaves me with 2850mm.

2850mm less 20mm gap in the centre of my two gates leaves me 2830mm

2830mm divided by two gives me 1415mm each as the width for my gates.

Your Automatic Solutions branch will help you choose hinges, motors etc. and advise deductions required. You can also e-mail us here for help and upload photos if you have them.

3. Now you want a height. In the example above I want a finished height of 1800mm. My centre stop for my gates requires a minimum clearance of 20mm and maximum of 40mm. I will deduct 25mm from my 1800 and make my gates 1775mm high. By the way based on this I can make my posts 2700 long (1800mm plus 900mm into the concrete) unless of course I am bolting my posts to the wall in which case I will cut them at 1800mm long.

Mounting your motor. Each motor will have a slightly different mounting method and dimensions but there are a number of key points to take into account when considering mounting your motor.

If your motor can swing from the centre of the gate vertically this will better than the bottom. Apart from a simple mechanical advantage it keeps it off the ground where dirt and dust will penetrate with ease. Your post mounted bracket can be fixed in a variety of ways. Welding is popular although we prefer using tek screws or bolting. Assuming you have used a reasonable thickness for your post (3mm) then the teks will hold perfectly well for normal operation but will in all likelihood shear if excess force is applied saving any damage to your motor and allowing easy refit. The bracket on your gate may need to be welded or bolted as this point takes a lot of pressure. Use tek screws to position and test. When happy with your result bolt or weld.

Gate Stops. All automatic gates require opening and closing stops for safety and programming. On single swing gates this generally means a good secure opening stop and often an electric gate lock takes care of the closing stop. Double gates is a little more complex as now we need two opening stops and a centre stop. Do not be tempted into using built in motor stops as a replacement for good solidly installed gate stops. The built in devices work ok on small open design gates as opening stops but cause nothing but frustration as closing stops. Put in good mechanical stops and save the maintenance and frustration.

Ready to power and program. At this point I assume you have had your power professionally connected and all other wiring has been completed. My simple suggestion is that you leave most extras like photo cell beams and keypads not connected and that you have all required loops installed until you have the gate programmed and running. Having bells and whistles connected will only complicate matters if things don;t go exactly as expected. By having the bare basics makes fault finding much easier.